Hot-rolled I-beams are structural steel products with a characteristic "I" cross-section, formed through a continuous rolling process. They feature a thick central web and narrower flanges, optimized for unidirectional bending resistance. Manufactured to meet standards like GB/T 706, they use high-strength steel grades to ensure durability and load-bearing capacity. Key advantages include precise dimensions (e.g., height tolerance ±3mm), uniform mechanical properties, and cost-effective production. Widely used in construction (building frameworks, bridges), machinery, and industrial equipment, their standardized sizes (100mm–630mm height) simplify installation and reduce on-site fabrication. Ideal for general structural applications requiring reliable performance and economy.

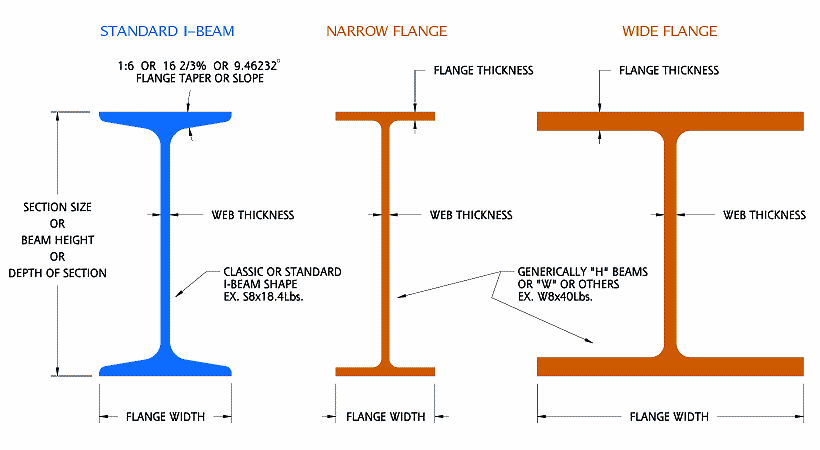

Differences Between I-Beams and H-Beams

I-Beams: Characterized by a thick central web and narrow, parallel flanges (e.g., 100mm–630mm height per GB/T 706), optimized for unidirectional bending resistance.

H-Beams: Feature a symmetrical "H" shape with wider, uniform flanges and a thinner web, offering balanced strength in both directions.

I-Beams: Excel in applications requiring resistance to bending in one plane (e.g., building frameworks, bridges).

H-Beams: Provide superior load-bearing capacity for heavy-duty, bidirectional loads (e.g., high-rises, industrial machinery).

I-Beams: Manufactured in standardized sizes with precise tolerances (e.g., height ±3mm), ideal for general construction.

H-Beams: Available in both hot-rolled (precise, cost-effective) and welded (customizable dimensions) forms, catering to specialized or non-standard projects.