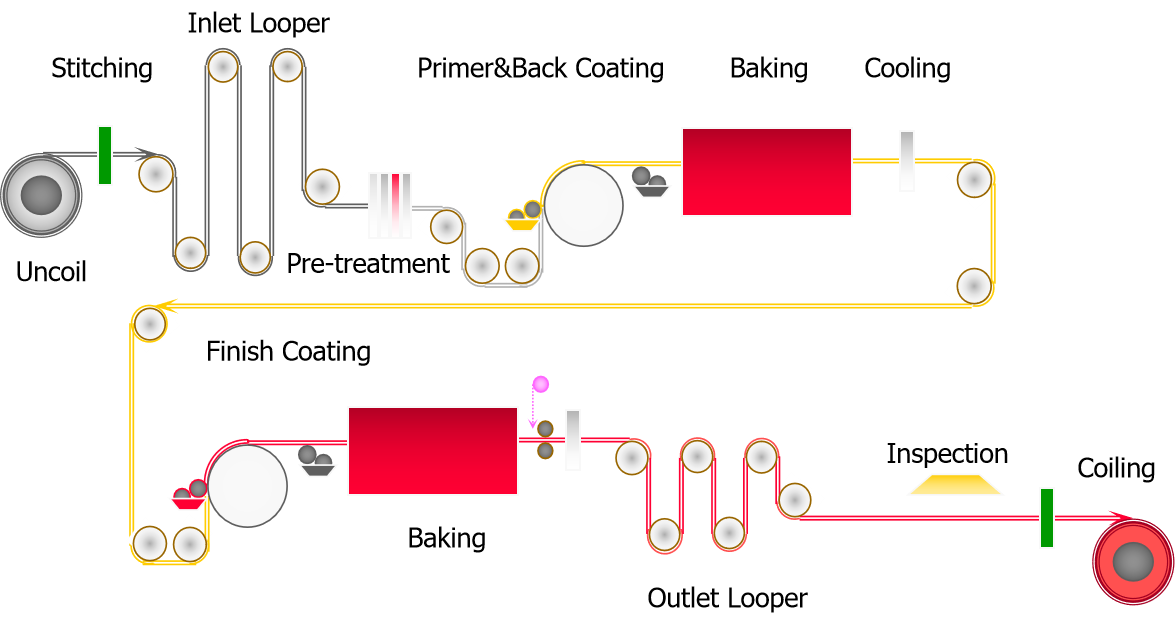

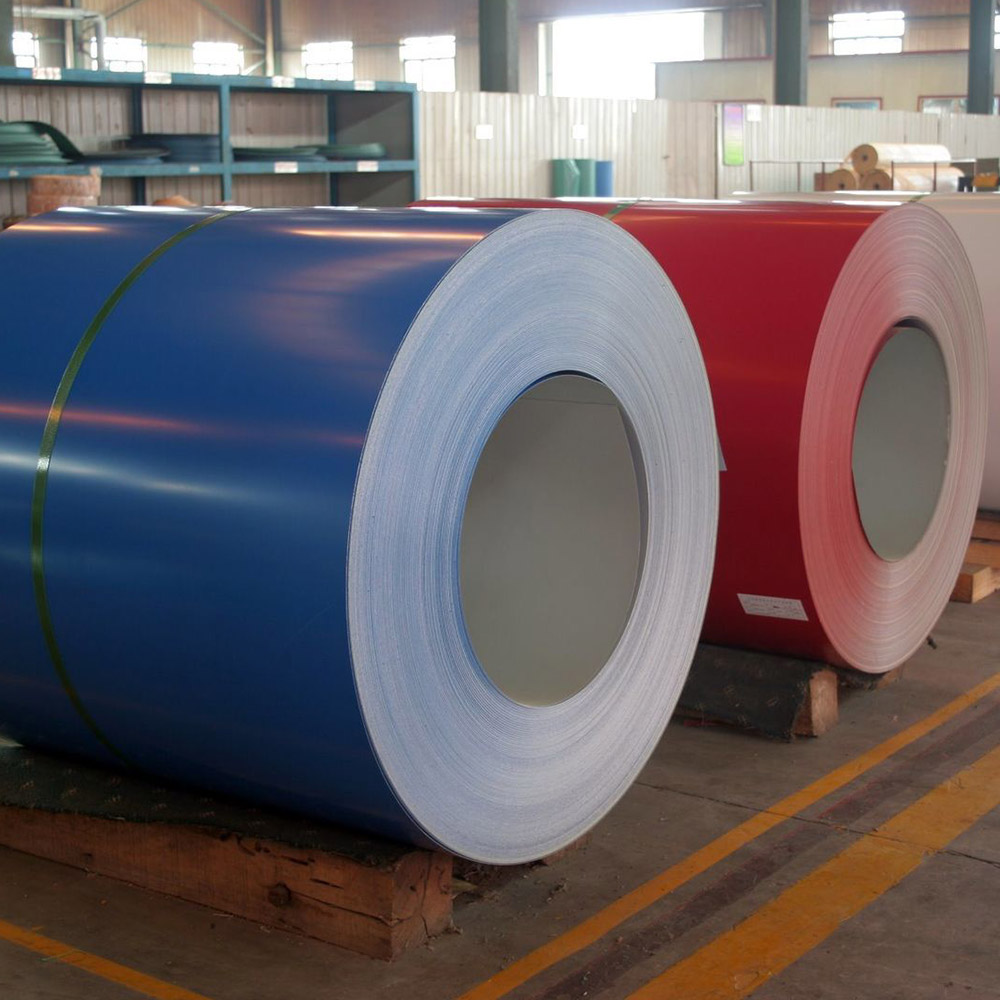

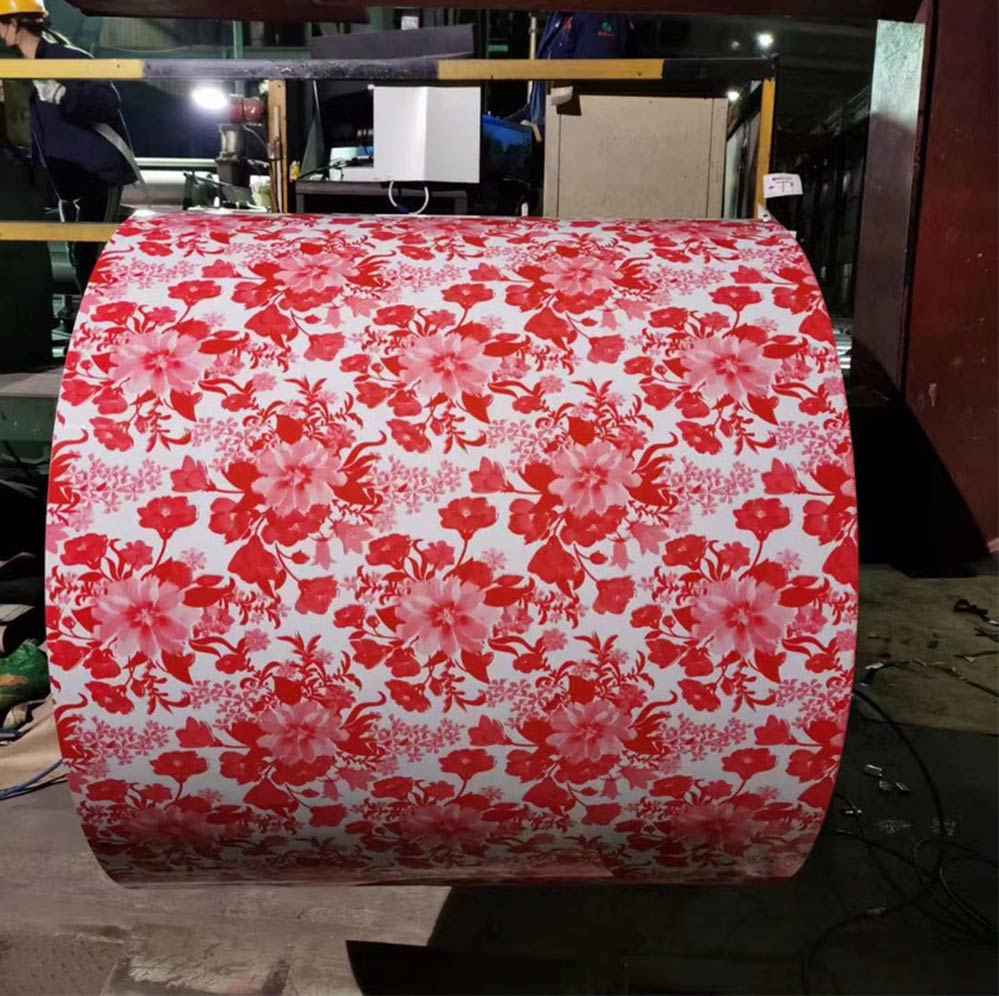

Color-coated steel coils, also known as pre-painted steel coils, are produced by applying organic coatings (e.g., polyester, PVDF, silicon-modified polyester) to galvanized or cold-rolled steel substrates. This process enhances corrosion resistance, weatherability, and aesthetic appeal. The coils undergo surface pretreatment, painting, and curing at high temperatures to form durable, vibrant finishes in various colors and textures. Widely used in construction (roofing, wall panels), automotive (door panels), appliances (refrigerators), and furniture, they offer lightweight yet robust solutions. Common grades include TDC51D+Z for general use and high-strength variants. Advantages include low maintenance, energy efficiency (cool roof coatings), and design flexibility. Surface treatments like embossing or printing further expand applications, balancing functionality with decorative needs in modern industries.

Advantages and Uses of Color-Coated Steel Coils