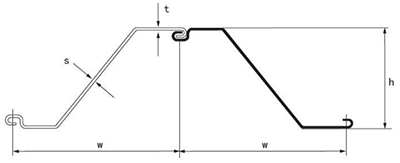

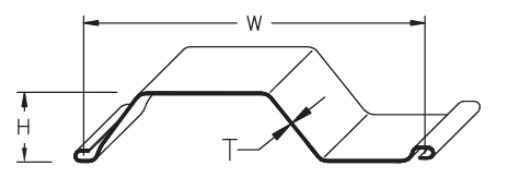

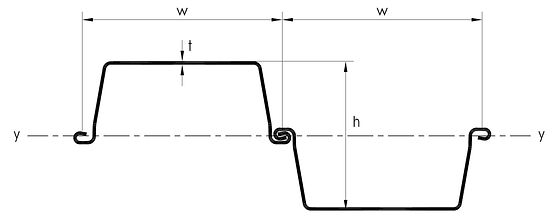

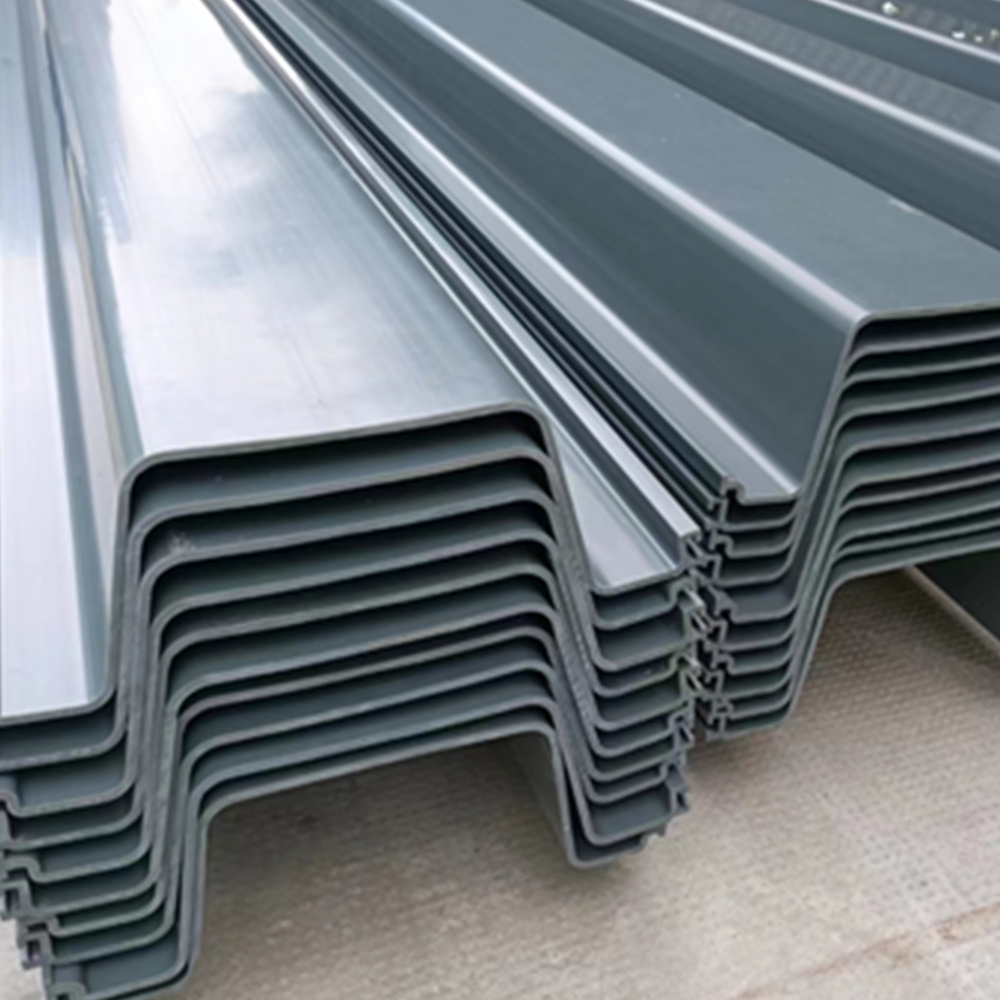

Cold-formed steel sheet piles are structural elements produced by bending or rolling steel plates at room temperature without heat. This process creates precise, lightweight profiles (e.g., U, Z, or custom shapes) with high strength-to-weight ratios. Widely used in construction, they offer flexibility for small-scale projects, temporary structures, and confined spaces. Their corrosion resistance, dimensional accuracy, and cost-effective installation make them ideal for retaining walls, slope stabilization, and shallow foundation works. Unlike hot-rolled piles, cold-formed variants allow rapid customization for specific site needs, though they may require additional coatings for enhanced durability in aggressive environments. Common materials include galvanized or painted carbon steel, balancing performance with environmental sustainability.

Advantages of Hot-Rolled Steel Sheet Piles