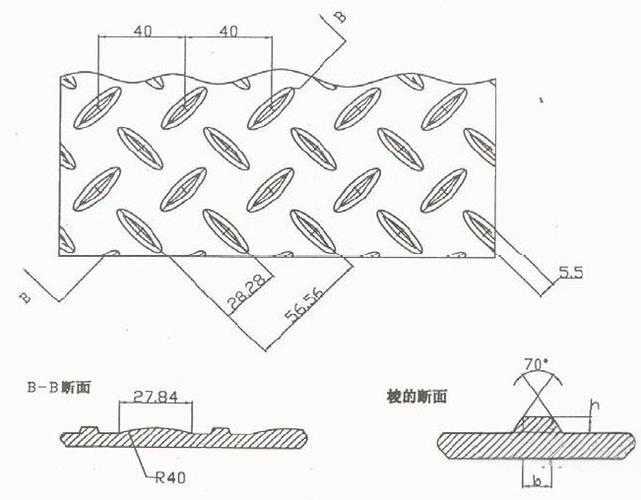

Checkered steel plates, also known as patterned or embossed steel plates, are flat steel sheets with raised geometric patterns (e.g., diamond, hexagonal, or ribbed designs) rolled into their surfaces during manufacturing. These patterns enhance slip resistance, structural rigidity, and visual appeal. Produced via hot or cold rolling processes, they are commonly made from low-carbon steel, stainless steel, or aluminum. The embossing improves grip in wet or oily environments while increasing surface area for better load distribution. Thicknesses range from 1.5mm to 12mm, depending on application. Widely used in construction (stairs, ramps), automotive (truck beds, trailers), shipbuilding (decks), and industrial flooring, checkered plates balance durability with functional aesthetics. Surface treatments like galvanization or painting may be applied to enhance corrosion resistance. Their versatility and cost-effectiveness make them ideal for safety-critical and decorative purposes.

Advantages and Uses of Checkered Steel Plates